Yüksek kaliteli Api 5ct Q125 petrol kılıf borusu boru ve muhafaza çelik muhafazalı boru

Yüksek kaliteli Api 5ct Q125 petrol kılıf borusu boru ve muhafaza çelik muhafazalı boru

| Miktar (Ton) | 1 - 1 | 2 - 100 | 101 - 10000 | > 10000 |

| Tahmini Zaman (gün) | 10 | 15 | 25 | Müzakere Edilecek |

|

Isıl işlem:

|

Tavlama, söndürme, nitrürleme, sertleştirme, tavlama, normalleştirme vb.

|

|

Tolerans

|

Çizim başına.(+/-0.05mm,+/-0.01mm)

|

|

Yüzey işleme:

|

Çinko kaplama, nikel kaplama, krom kaplama, eloksal, fosfatlama, kimyasal kararma, tuz banyosu nitrürleme, vb.

|

|

Kurşun zamanı:

|

20-45Days miktarlara ve karmaşıklığa bağlıdır

|

|

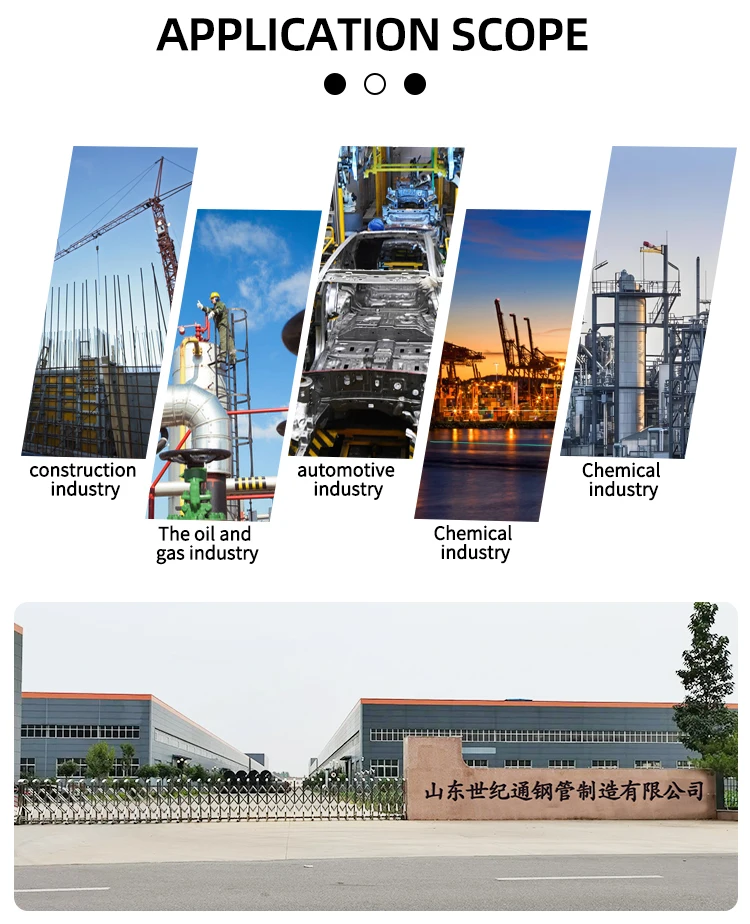

Uygulama

|

Forklift, vinç, tren, kamyon, çim biçme makinesi, demiryolu yol Euipment, tıbbi cihaz, endüstriyel makine, otomobil, elektrik

Cihaz, otomasyon makinesi, diğer endüstriler, vb, |

|

Ödeme süresi:

|

L/C sightT/T % 30% mevduat ve sevkiyat öncesi ödemek için dengeli 70%.

|

|

Üretim ekipmanları:

|

CNC işleme makinesi, CNC torna, taşlama makinesi, freze makinesi, testere makinesi, KAYNAK MAKINESİ, hidrolik pres makinesi, sondaj

Ve dokunarak makinesi, dişli şekillendirme makinesi, vb. |

|

Inceleme ekipmanı:

|

Elektronik Penumatic ölçüm cihazı, üç Coodinate tespit cihazı, Rockwell sertlik test cihazı, dijital ultrasonik kusur

Dedektör, yüzey pürüzlülüğü ölçüm cihazı, Leeb sertlik test cihazı, kaplama ölçüm cihazı, tuz püskürtme test cihazı, dişli Ölçüm merkezi, vb. |

|

QC

|

1. Gelen malzeme production.2.Strict işleme kalite kontrol önce kontrol edilecektir.

Sevkiyat öncesi % 3.100% muayene. 4. Son kullanıcıya ürün kalitesinden sorumluyuz. |

|

Paket

|

Yöntem 1: karton kutu veya oluklu karton

Yöntem 2: tahta sandık veya ahşap sandık Yöntem 3: demir sepet veya plastik sepet Yöntem 4: palet |

|

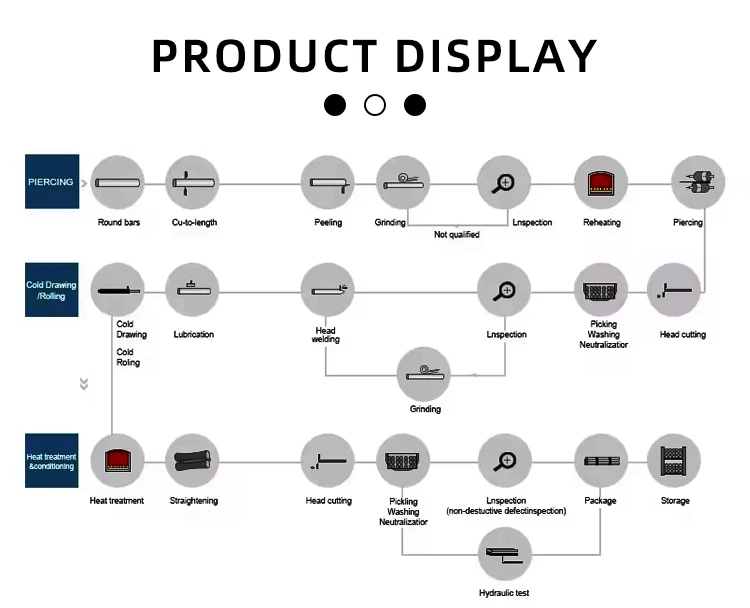

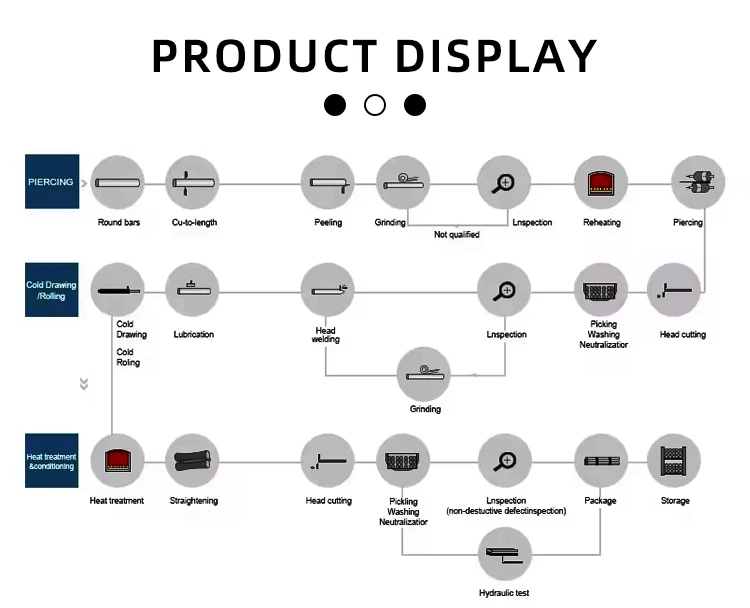

Heat Treatment:

|

Annealing,Quenching,Nitriding,Hardening,Tempering,Normalizing,etc.

|

|

Tolerance

|

As per drawing.(+/-0.05mm,+/-0.01mm)

|

|

Surface Treatment:

|

Zinc-Plated,Nickel-Plated,Chrome-Plated,Anodize,Phosphating,Chemical Blackening,Salt Bath Nitriding,etc.

|

|

Lead Time:

|

20-45Days Depends On Quantities and complexity

|

|

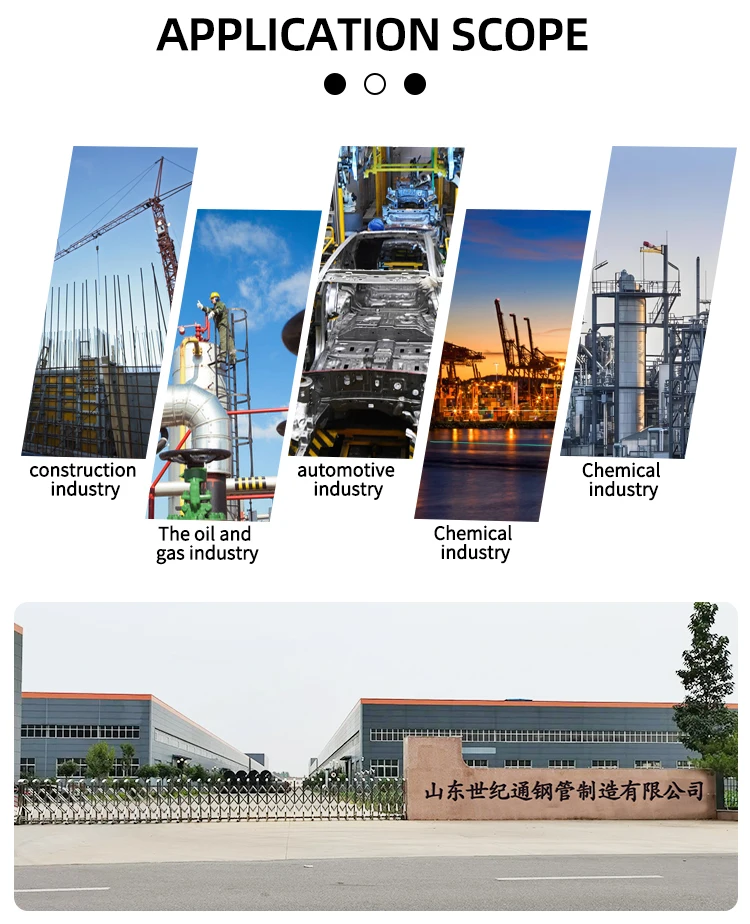

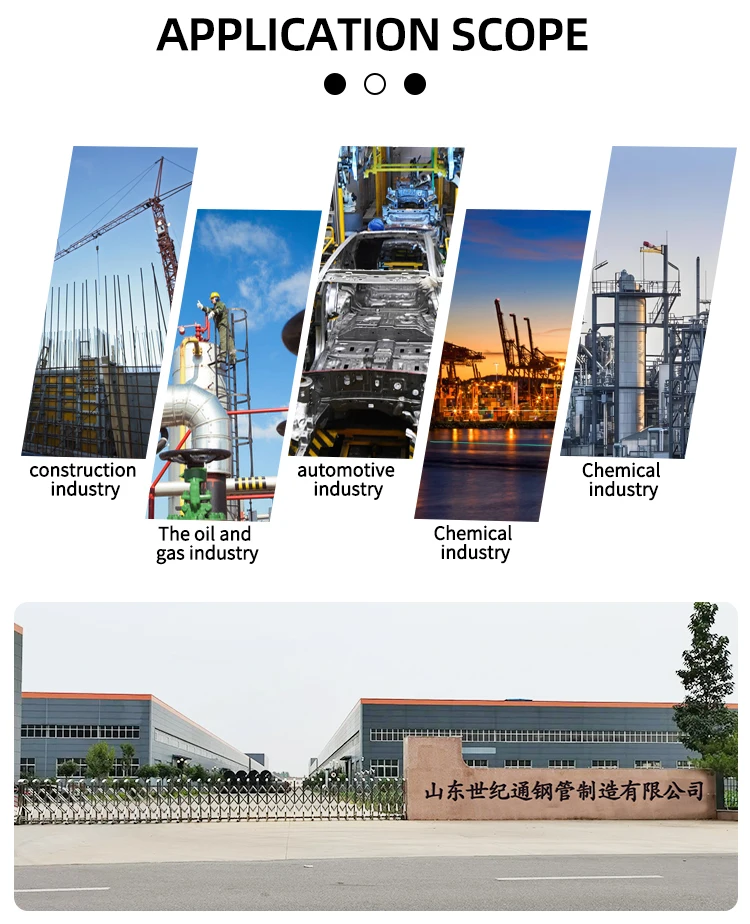

Application

|

Forklift,Crane,Train,Truck,Lawnmower,Rail Road Euipment,medical device, industrial machine, automobile, electric

appliance,Automation machine,other industries,etc, |

|

Payment Term:

|

L/C at sightT/T 30% deposit and balanced 70% to pay before shipment.

|

|

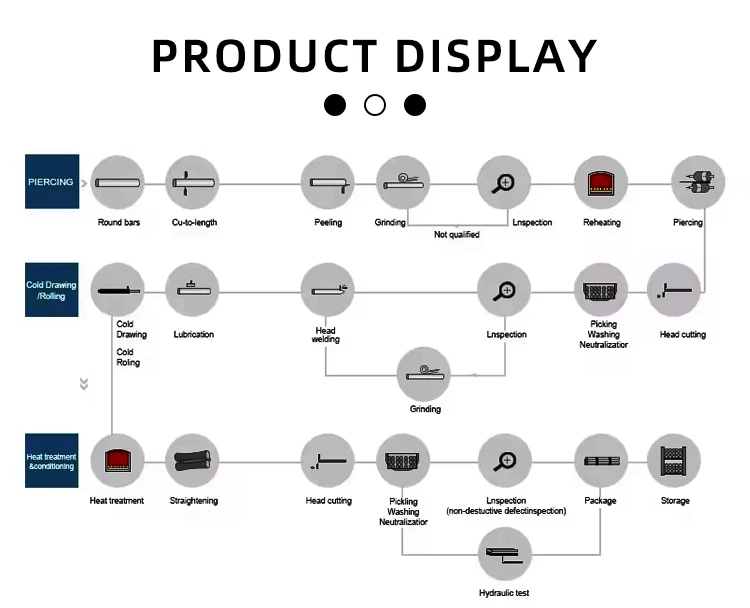

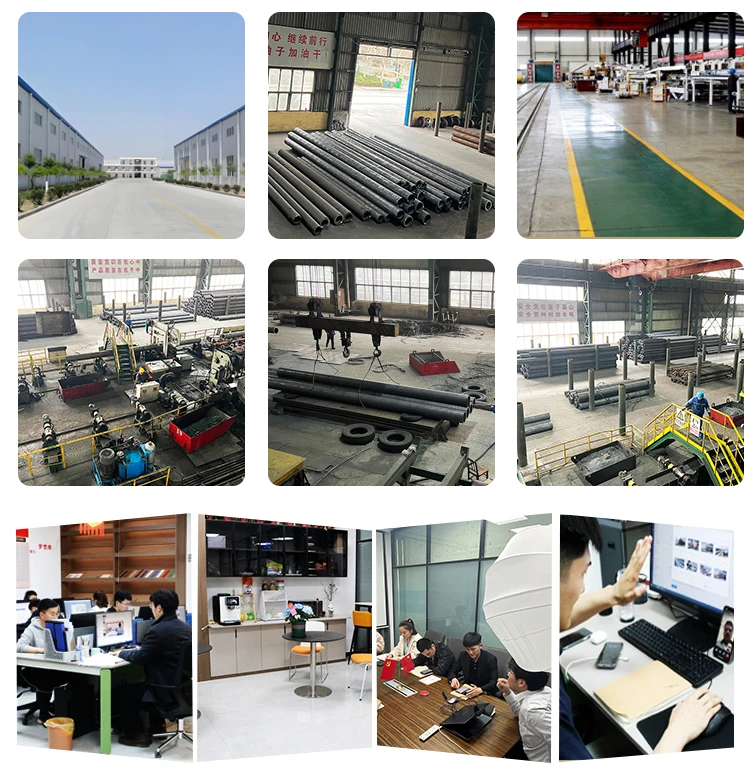

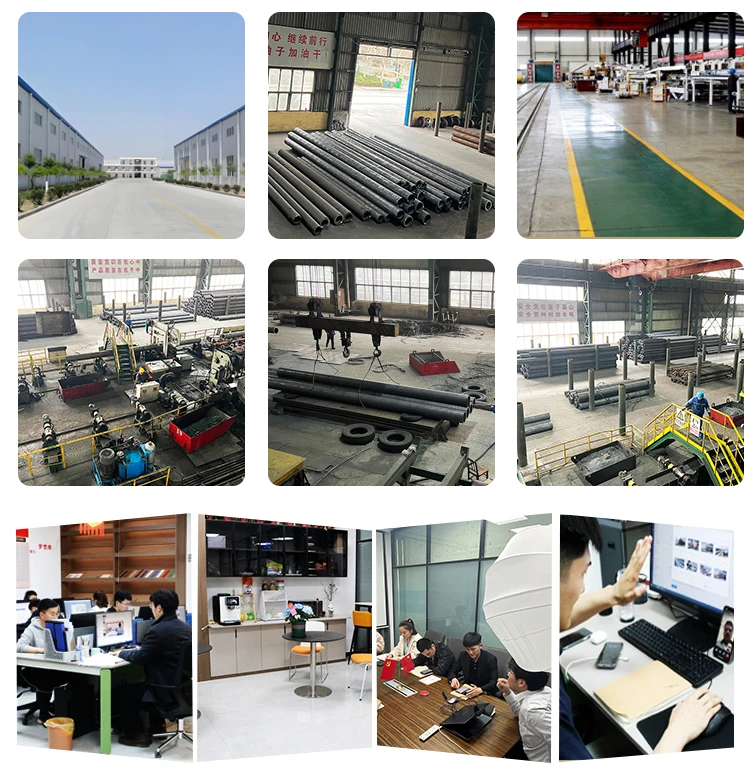

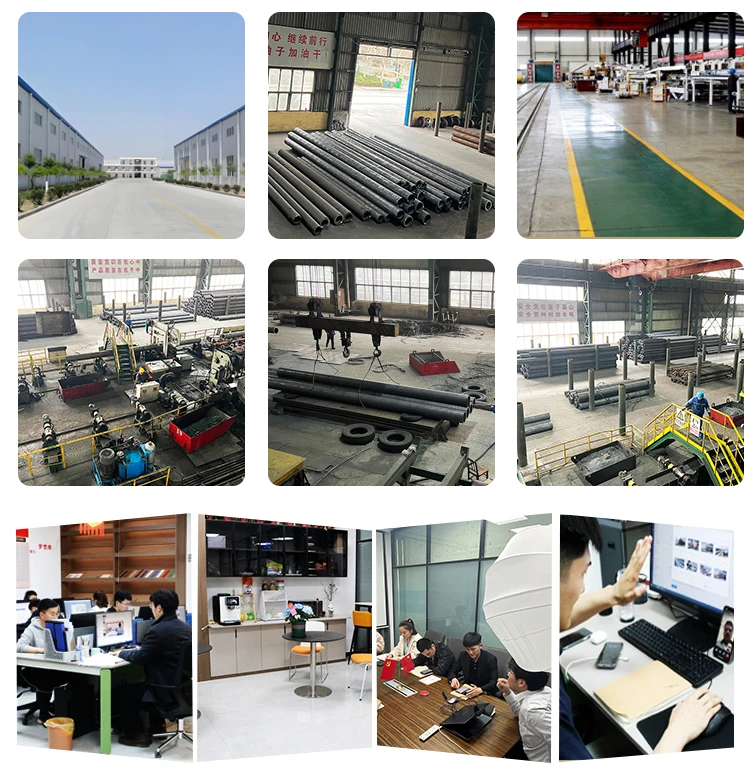

Production Equipment:

|

CNC Machining center,CNC Lathe,Grinding Machine,Milling Machine,Sawing Machine,Welding Machine,Hydraulic Press Machine,Drilling

and Tapping Machine,Gear Shaping Machine,etc. |

|

Inspection Equipment:

|

Electronic Penumatic Measuring Instrument,Three Coodinate Detection Equipment,Rockwell Hardness Tester,Digital Ultrasonic Flaw

Detector,Surface Roughness Measuring Instrument,Leeb Hardness Tester,Cladding Measuring Instrument,Salt Spraying Tester,Gear Measurement Center,etc. |

|

QC

|

1.Incoming material will be checked before production.2.Strict processing quality control.

3.100% inspection before shipment. 4.We are responsible for product quality to the end user. |

|

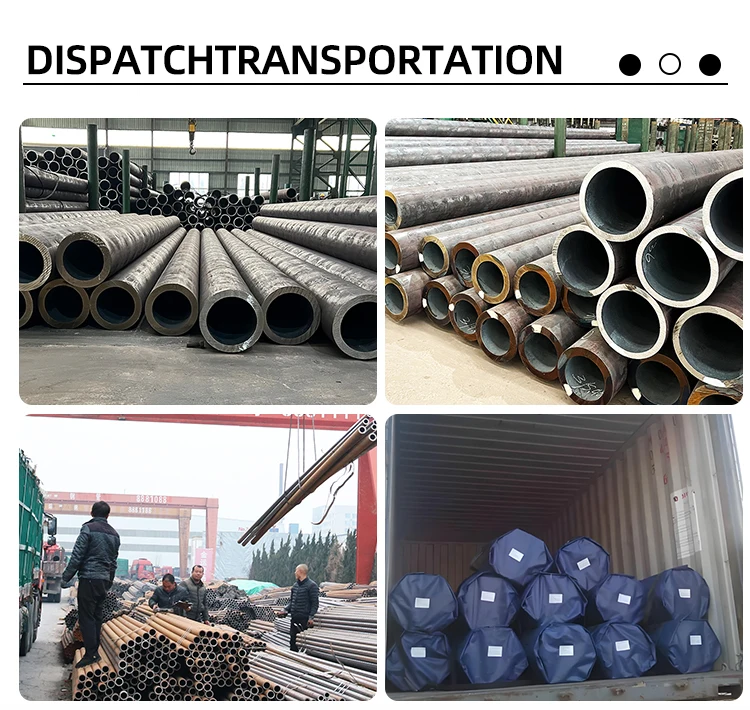

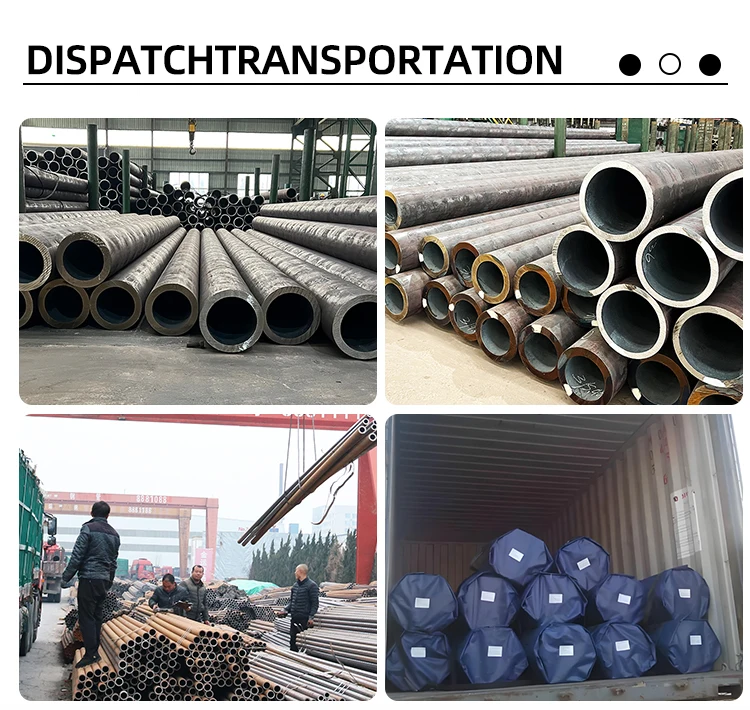

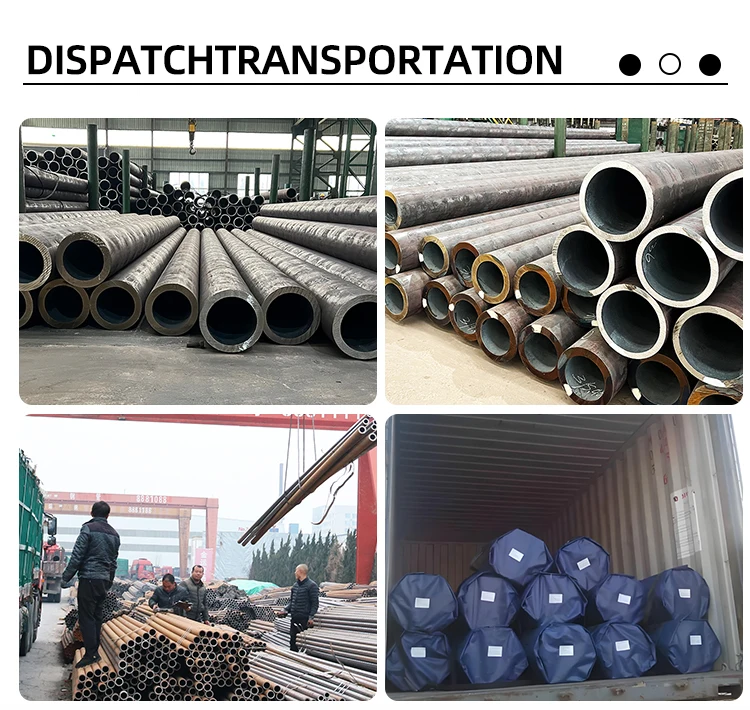

Package

|

Method 1:Carton box or corrugated carton

Method 2:Wooden case or wooden crate Method 3: Iron basket or plastic basket Method 4: Pallet |

|

Heat Treatment:

|

Annealing,Quenching,Nitriding,Hardening,Tempering,Normalizing,etc.

|

|

Tolerance

|

As per drawing.(+/-0.05mm,+/-0.01mm)

|

|

Surface Treatment:

|

Zinc-Plated,Nickel-Plated,Chrome-Plated,Anodize,Phosphating,Chemical Blackening,Salt Bath Nitriding,etc.

|

|

Lead Time:

|

20-45Days Depends On Quantities and complexity

|

|

Application

|

Forklift,Crane,Train,Truck,Lawnmower,Rail Road Euipment,medical device, industrial machine, automobile, electric

appliance,Automation machine,other industries,etc, |

|

Payment Term:

|

L/C at sightT/T 30% deposit and balanced 70% to pay before shipment.

|

|

Production Equipment:

|

CNC Machining center,CNC Lathe,Grinding Machine,Milling Machine,Sawing Machine,Welding Machine,Hydraulic Press Machine,Drilling

and Tapping Machine,Gear Shaping Machine,etc. |

|

Inspection Equipment:

|

Electronic Penumatic Measuring Instrument,Three Coodinate Detection Equipment,Rockwell Hardness Tester,Digital Ultrasonic Flaw

Detector,Surface Roughness Measuring Instrument,Leeb Hardness Tester,Cladding Measuring Instrument,Salt Spraying Tester,Gear Measurement Center,etc. |

|

QC

|

1.Incoming material will be checked before production.2.Strict processing quality control.

3.100% inspection before shipment. 4.We are responsible for product quality to the end user. |

|

Package

|

Method 1:Carton box or corrugated carton

Method 2:Wooden case or wooden crate Method 3: Iron basket or plastic basket Method 4: Pallet |

Chovm.com'da yaptığınız her ödeme sıkı SSL şifreleme ve PCI DSS veri koruma protokolleri ile güvence altına alınır

Siparişiniz gönderilmezse, eksik ise veya ürün sorunları ile gelirse geri ödeme talep edin